Built to Be Busy: Materials That Thrive Under Heavy Footfall

What Low-Maintenance Really Means on the Job

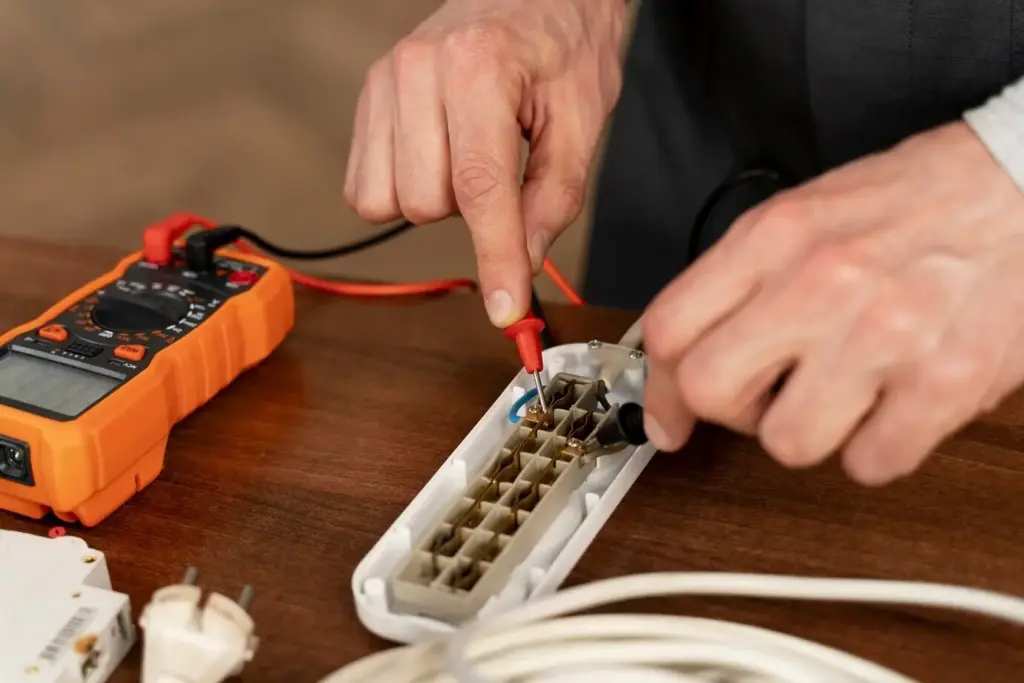

Durability You Can Measure

Request data like Taber abrasion results, impact resistance, and scratch testing where relevant. Compare manufacturer maintenance schedules and warranty limits against your actual traffic peaks, including shift changes, public events, or student dismissals. Specify finishes built to tolerate routine disinfecting without clouding, and ask about repair kits or spot-blend options. Durable choices should show consistent appearance retention, not just strength on paper, ensuring both performance and presentability over years of unrelenting use.

Cleaning in Minutes, Not Hours

Materials that release dirt easily, tolerate automatic scrubbing, and require no frequent sealing are your allies. Prioritize surfaces that respond to neutral cleaners and microfiber, sidestepping harsh chemicals that raise costs and risks. Look for integrated base details that eliminate grime-catching edges, and finishes that resist black heel marks. When daily routines are simple, staff morale rises, overtime shrinks, and your facility stays open and inviting even after the busiest rushes or unexpected messes.

True Cost Over the Full Life

Initial price is only one line item. Add labor, chemicals, machine time, water, energy, replacement cycles, and disruption costs to reveal real value. A finish that needs no waxing or sealing can free thousands of dollars every year. Map maintenance steps task-by-task, then multiply by realistic frequencies. Compare a five- or ten-year horizon, including downtime. Facilities that prioritize low-maintenance consistently report steadier budgets, calmer operations, and fewer emergency interventions after inevitable spikes in foot traffic.

Floors That Welcome Crowds and Wear Gracefully

Compact Laminate and Phenolic Panels

Solid Surface and Quartz Worktops

Wall Protection That Saves Paint

Stainless That Hides Fingerprints

Powder Coats That Endure

PVD for Color Without Chipping

Restrooms and Wet Zones Made Effortless

Right Chemicals, Lower Effort

Schedules and Machines That Do the Work

All Rights Reserved.